Modern dental surgery allows implantation of titanic screws, implants in upper or lower jaw. After a period of time needed for osseointegration or splicing of a bone with the dental implant, it is possible to place prosthetics on such implants, such as crowns, bridges or dentures.

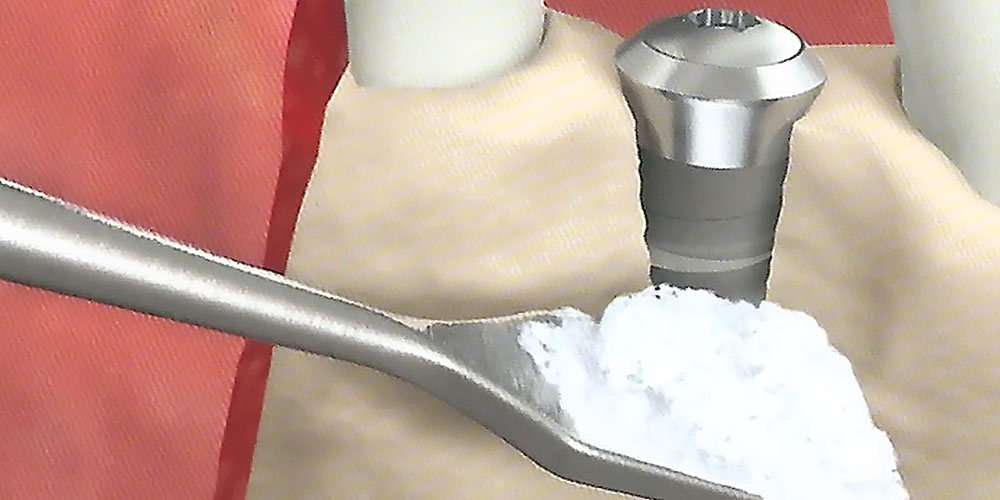

Our professional team is also capable of more complex surgical treatments such as sinus lifting (lifting of the floor of a maxillary sinus), bone augmentation in cases of insufficient bone when is not possible to place an implant immediately. In such cases indication for implantation becomes much wider and even difficult cases of bone loss can be treated with implants.

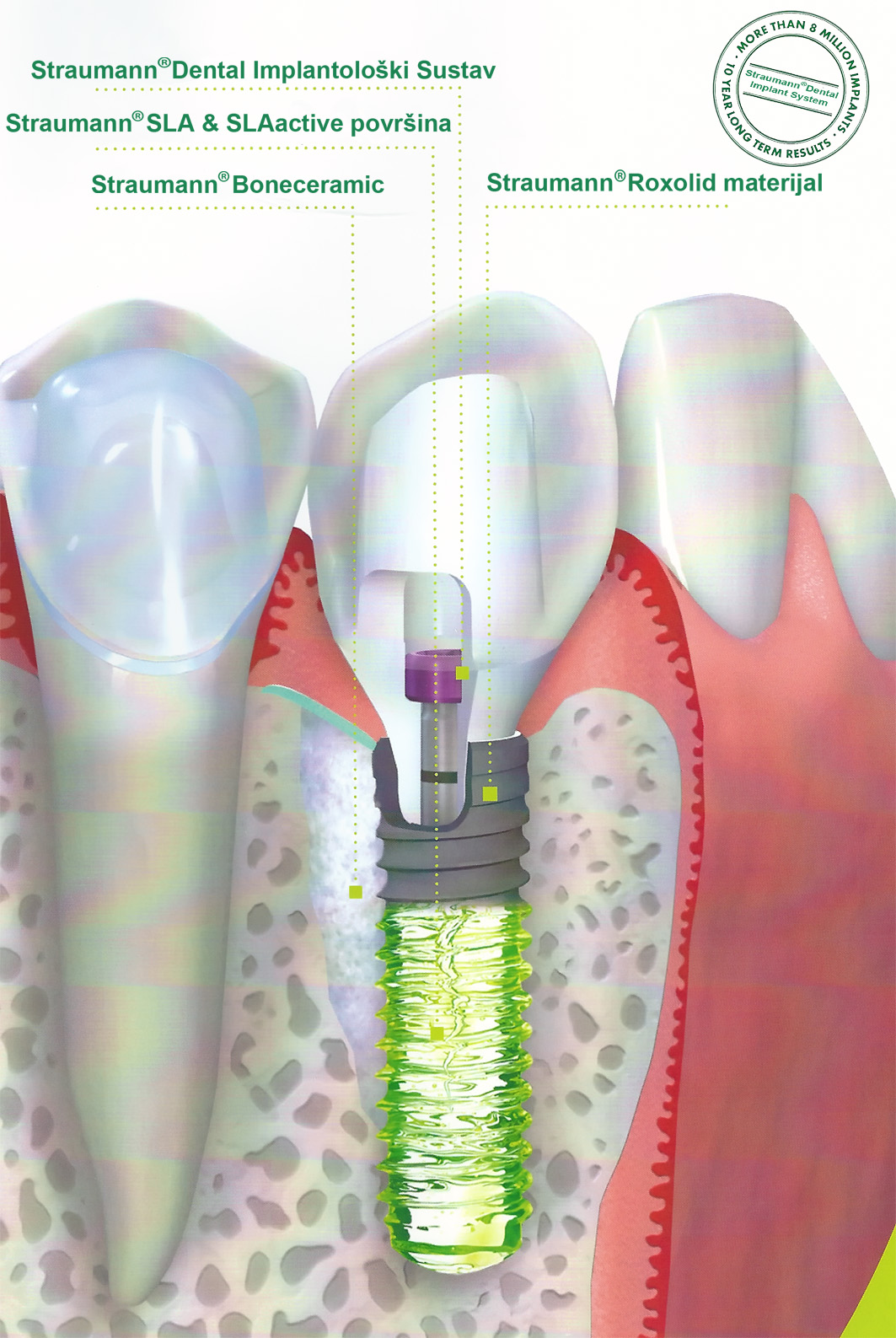

All implants and other materials that are used in our surgery are made in the European Union. We work with the Swiss made Straumann SLA Bone Level implants, Geislich BioOss bone for augmentation and Biotiss DentaGeistlich Biogidel (made in CH) materials for modelation of maxillary sinus or a bone.

Preoperative analysis is made on a digital X-ray system and the 3D Cone Beam technology (CBCT) in order to decrease radiation in those treatments to a minimum (70 % less than a regular X-ray).

Improvements in implant materials are introduced with implants such as Roxolid and Straumann that are made of titanium and zirconium. This provides for increased hardness of the material resulting in better clinical performance and giving larger indication for implant treatment. The SLA-active surface provides for faster osseointegration and better quality or bone-implant connection. This has led to Straumann winning a 2005 Award for Innovation of Technology in Medicine. More than 1.400 scientific and clinical studies’ have been conducted in order to test Straumann implant system and that is the reason why those implants are safe to use and are giving best results.

Journal of Dental Research. 2016 95: 43–49. Effectiveness of Implant Therapy Analyzed in a Swedish Population:Prevalence of Peri-implantitis. The investigators observed that the extent of moderate/severe peri-implantitis2 differed between the implant systems and that the odds ratio of developing it was more than three times higher in the patients treated with Nobel Biocare and Astra Tech Implant System implants. With some exceptions, the Nobel Biocare implants had a TiUnite® surface and the Astra Tech implants had a TiOblast® surface; all the Straumann implants were Tissue Level SLA®.The results, which were presented at the 2015 EAO and have now been published in the Journal of Dental Research 1 , add weight to previously reported findings showing high success rates with Straumann implants3,4,5,6,7. The findings are highly relevant for dentists who base their choice of implant on independent clinical evidence.

Clin Oral Implants Res. 2011 Aug 18. doi: 10.1111/j.1600-0501.2011.02296.x. Titanium-zirconium alloy narrow-diameter implants (Straumann Roxolid(®) ) for the rehabilitation of horizontally deficient edentulous ridges: prospective study on 18 consecutive patients.Narrow diameter implants fabricated with the new titanium-zirconium alloy were demonstrated to be reliable in supporting both fixed and removable prosthetic rehabilitations in horizontally deficient ridges. Implant survival, peri-implant bone resorption, and prosthetic complication rates were consistent with those reported in the literature for standard diameter implants placed in non-deficient edentulous ridges.

Clin Oral Implants Res. 2011 Jun 24. doi: 10.1111/j.1600-0501.2011.02231.x. ] A pilot study to evaluate the success and survival rate of titanium-zirconium implants in partially edentulous patients: results after 24 months of follow-up. Within the limits of this pilot study, the performance of the new implant material was safe and reliable. The new implants meet established success and survival criteria after 2 years.

Clin Implant Dent Relat Res. 2010 Jun 25. Evaluation of a New Titanium-Zirconium Dental Implant: A Biomechanical and Histological Comparative Study in the Mini Pig. It is concluded that the TiZr1317 implant with a hydrophilic sandblasted and acid-etched surface showed similar or even stronger bone tissue responses than the Ti control implant.

Also, you can find more than 400 published scientific papers about Straumann implants, which cheap implants or copy/paste implants can not have.

First Straumann implant had been manufactured in 1974 and it was successfully clinically tested at the University of Bern, Switzerland. Since 2004 much cheaper implants have been offered on the market and by that time Straumann implants had over 20 years of experience in implantology with scientific and clinical evidence conducted in renown scientific magazines. We have been working with Straumann Roxolid implants since 2009 after introduction of Roxolid on the dental market.

Firstly, Straumann is a world-leading company in manufacturing of implants. A proof of such statement is the largest number of scientific papers published in renowned scientific journals and papers. Secondly, Straumann Company continuously invests in new clinical trials making their implants more and more advanced over the years. Not all implant systems are the same, many companies are just trying to copy general design of famous and more expensive implants, without investing in clinical and scientific trials. With those kinds of implants a large possibility of unsatisfactory results can be expected. Lack of active surface of the implant leads to lower strength of bond between implant and surrounding bone, and may even result in rejection or loss of implant. Another very important part is the abutment-part of an implant that a crown will be cemented on. It is much cheaper to improvise and try to make the abutment in the dental laboratory from non-titanium materials or cheap non pure titanium. But that kind of abutment which is not made of titan does not have those mechanical and physical characteristics needed for good and long-term function. Micro-movements are inevitable in such cases leading to failure. This is the reason why we use only original Straumann implants and abutments and together with the manufacturer we are giving a warranty for each part. The Straumann Company gives a 10-year warranty when an original implant and abutment are used.

The new Straumann® Pro Arch for screw-retained hybrid restorations combines several treatment steps which reduce complexity without compromising the outcome. From planning and implant placement to the final restoration, the entire treatment is seamless for the patient.

Respecting individual patients’ needs and expectations, the new Straumann® Pro Arch offers dental professionals all the components needed to provide a seamless edentulous treatment.

-Roxolid® – reducing invasiveness with smaller implants

-Roxolid material with excellent mechanical properties

– Roxolid may allow the use of smaller-diameter implants with the same clinical performance as regular-diameter titanium implants

-Smaller implants have the potential to preserve peri-implant structures and avoid invasive bone grafting procedures

-Create a full denture on two Roxolid 3.3 implants

-Increase patient acceptance of implant treatment by providing less invasive solutions

-Slactive® – designed to maximize treatment success and predictability

-Faster osseointegration to enhance confidence in all treatments5

-Reduced healing time from 6 to 8 weeks to 3 to 4 weeks

-Increased predictability in stability critical treatment protocols

-Increased efficiency with new prosthetic portfolio

-Prosthetic flexibility due to smaller abutment dimensions and different angulations

-Comprehensive portfolio for immediate temporization

-Custom-milled bar designs as a framework for final fixed bridges

-Accessibility for every lab

BLT implant provides flexibility in challenging clinical and anatomical situations. It represents a combination of the time-tested Straumann Bone Level Roxolid® SLActive® implant with the advantages of a tapered design. The Roxolid material has been specifically designed for dental implantology and delivers outstanding mechanical properties. Combined with the SLActive surface, Straumann delivers an excellent implant system with outstanding osseointegration and healing properties.

The Straumann® Screw-retained Abutment provides a wide range of prosthetic options for screw-retained restorations. A low abutment profile as well as various angulations and gingiva heights offer you flexibility to provide an individual solution for edentulous patients, including restoring posterior-tilted implants.

*Roxolid – reducing invasiveness with smaller implants

*Roxolid material with excellent mechanical properties

*Roxolid may allow the use of smaller-diameter implants with the same clinical performance as regular-diameter titanium implants3

*Smaller implants have the potential to preserve peri-implant structures and avoid invasive bone grafting procedures

*Create a full denture on two Roxolid 3.3 implants

*Increase patient acceptance of implant treatment by providing less invasive solutions

*SLActive – Designed to maximize treatment success and predictability

*Faster osseointegration to enhance confidence in all treatments5

*Reduced healing time from 6 to 8 weeks to 3 to 4 weeks5

*Increased predictability in stability critical treatment protocols

*Apically tapered – matches the natural shape of a tooth root

*Helps overcome anatomical restrictions

*In combination with the hybrid tapered shape, the cutting notches enable placement in underprepared sites

Straumann gives a guarantee of lifetime on all products. Only when used with genuineStraumann ® implants and abutments, and during this period is important to kept the serial number. It is very important to have a booklet on Straumann implants in which there is evidence of the original parts Straumann.

Straumann implants and abutments can be verified online through the serail numbers (LOT and REF) provided for each Straumann product.